Optimised belt conveyors for efficient material transport

Discover our high-quality belt conveyors, which offer an efficient and reliable solution for your material transport. With years of experience and customised solutions, we support various industries in optimising their conveying processes. Find out more about our versatile belt conveyors and find the right solution for your requirements.

Our belt conveyors offer many features and benefits:

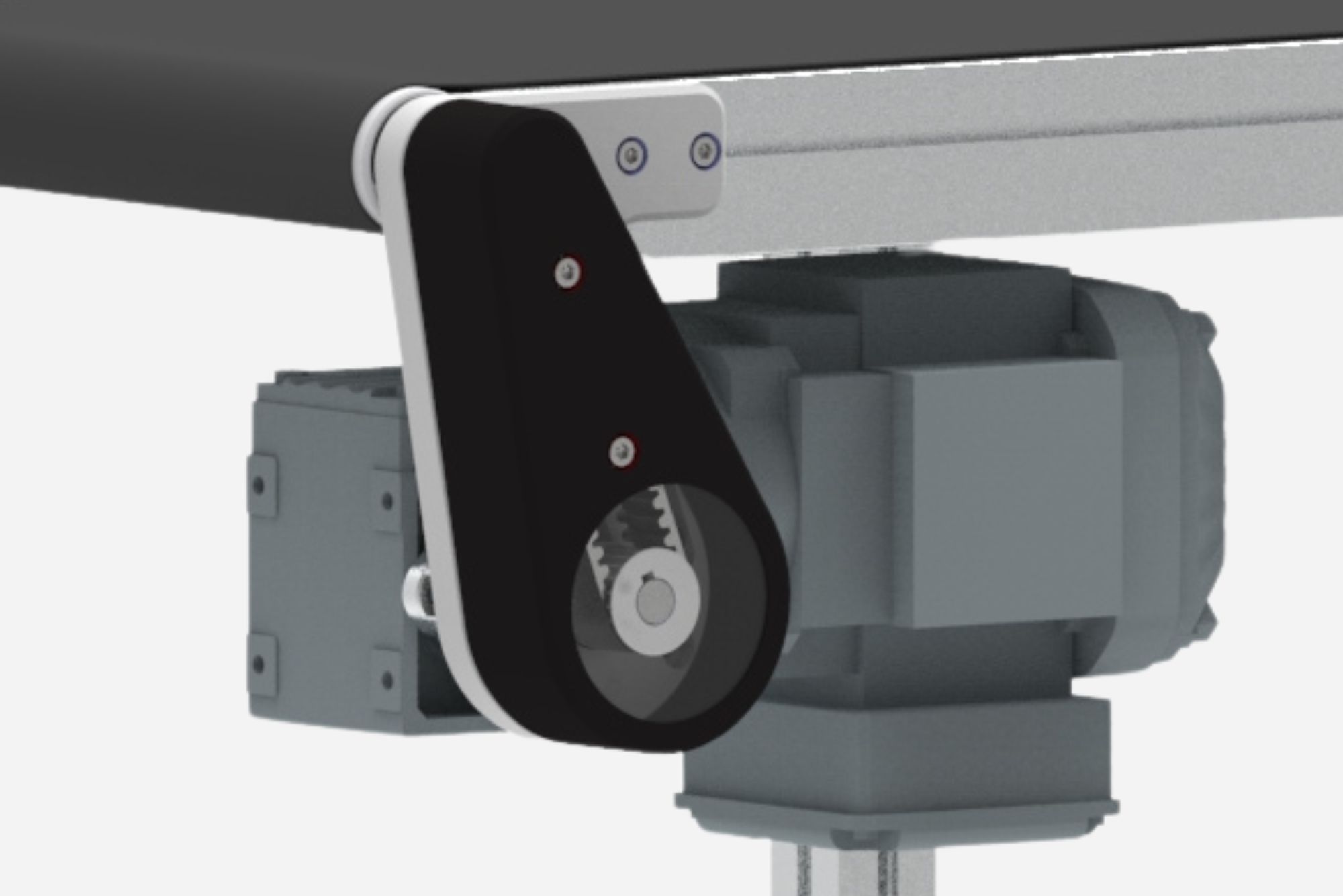

- Viewing window in the belt drive for monitoring and control

- Versatile application options thanks to the aluminium profile frame:

- Continuous flat sliding plate guide, anti-trap protection, integrated groove

- for side loading and unloading and much more.

- Connecting plate underframe as an assembly aid

- and much more.

Technical data belt conveyor

| SERIES | BELT CONVEYOR 40 | BELT CONVEYOR 80 |

| Width (mm)* | 140 - 600 | 400 - 1,200 |

| Length (mm) | 500 - 6'000 | 600 - 12'000 |

| Total load (kg) | up to 100 | up to 200 |

| Speed (m/min) | 2 - 44 | 4 - 79 |

| Ambient temperature (°C) | +5 to +45 | +5 to +45 |

Webinar Conveyor technology

The planned webinars will be published soon.

Documentation

Brochure Belt conveyor

The 6-page flyer provides a comprehensive overview of Kanya conveyor technology.

Frequently asked questions and answers (FAQ)

How is a belt conveyor constructed?

The structure of a belt conveyor comprises the following main components:

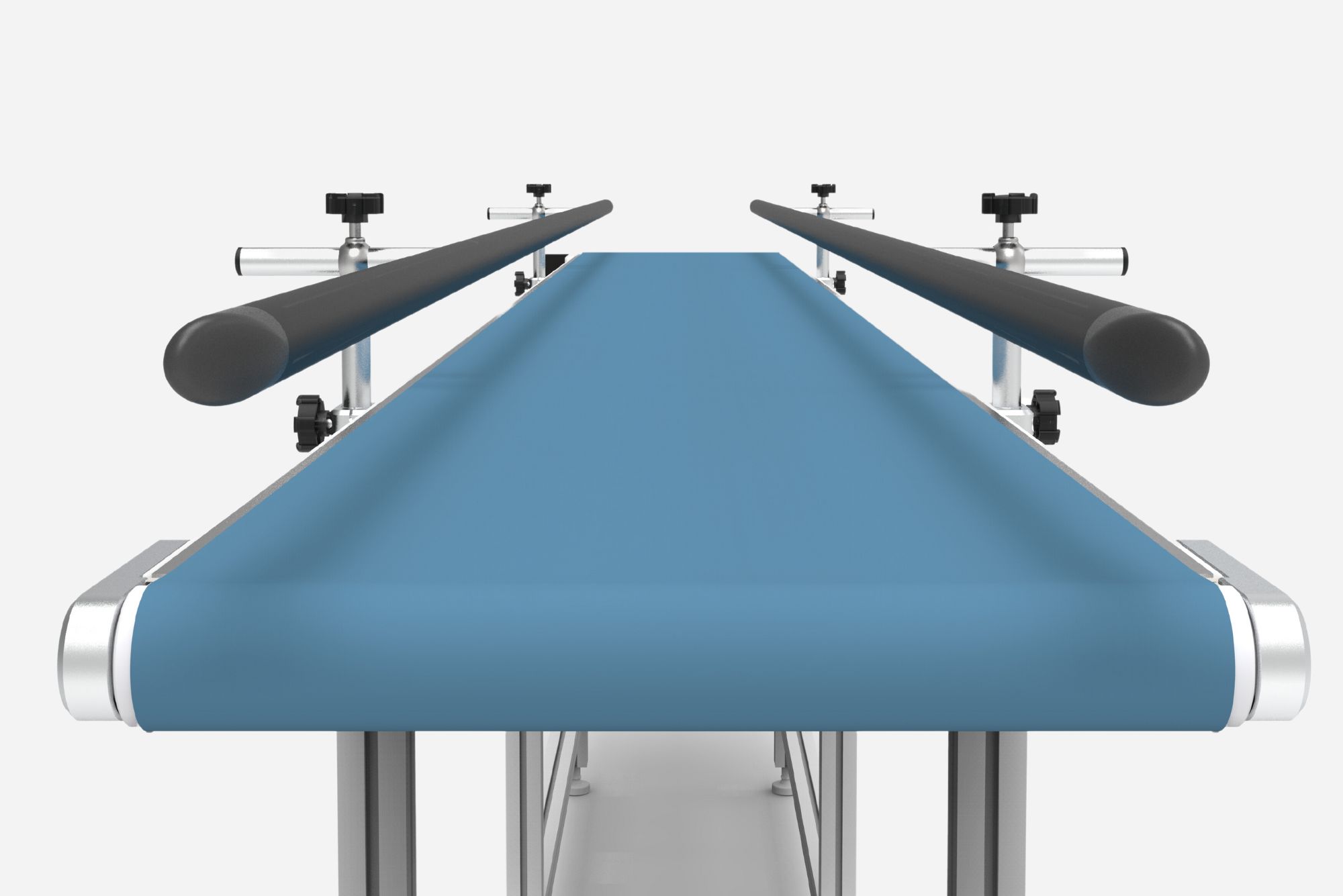

- Base frame made of aluminium profiles provides stability (h-shaped, wide h-shaped or central design)

- Aluminium profile frame with sliding plate

- Deflection deflects the conveyor belt and enables it to run continuously

- Drive consists of a motor and a gearbox that drive the conveyor belt

- Conveyor belt/belt is available in various materials, widths and surface structures, depending on the application requirements

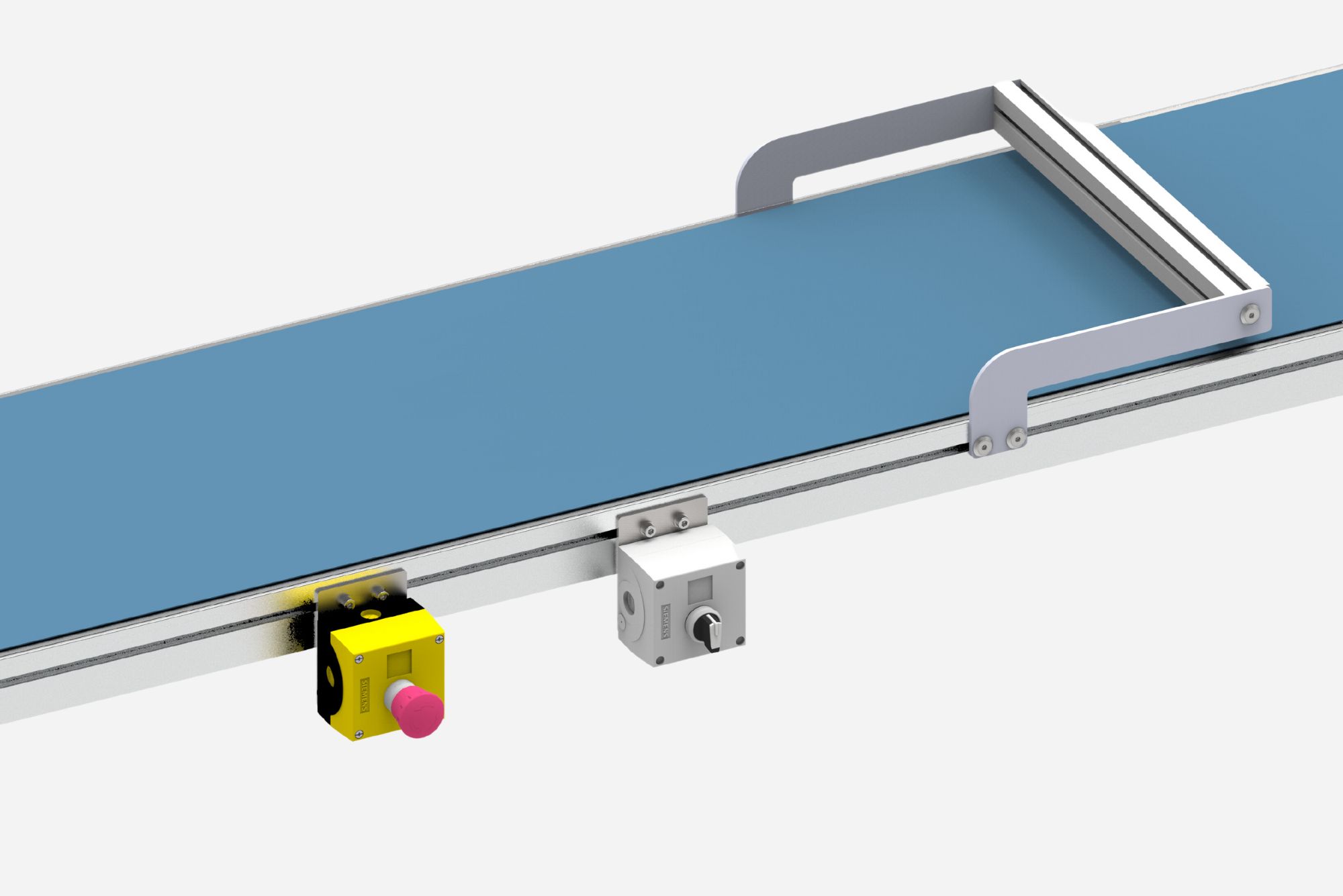

- Optional side guides can be fitted to centre the material on the belt and prevent it from falling off

- Additional accessories such as frequency converters, emergency stop switches, dust hoops, etc.

How do I determine the right size and type of belt conveyor for my application?

Die Auswahl des richtigen Gurtförderers hängt von mehreren Faktoren ab, einschließlich des Typs und Gewichts des Materials, das transportiert werden soll, der erforderlichen Transportgeschwindigkeit, und der Gesamtlänge und Steigung der Transportstrecke. Nutzen Sie unseren Online-Konfigurator, um Ihre individuell angepasste Lösung präzise zu bestimmen.

How fast can belt conveyors transport material?

The speed of a belt conveyor can vary and is tailored to the specific requirements of your material handling process. Factors that influence the transport speed include the weight and type of material as well as the length and incline of the conveyor.

Which motor is suitable for a belt conveyor?

The choice of motor for a belt conveyor depends on various factors, including the type of material to be transported, the conveyor section, the required speed and the operating conditions. Our selection of motors for belt conveyors:

Direct head drive: Motor connected directly to drive shaft via coupling

Indirect head drive: Drive roller is connected to the drive via a toothed belt

Direct centre drive: Can be positioned along the entire length

Indirect centre drive: Can be positioned along the entire length

Drum motor: Used as a drive roller

More information about the drive types.

Where can I find the operating instructions for the belt conveyor?

You can find the operating instructions for your belt conveyor here: ...

and as a QR code stuck directly onto the device. Simply scan this QR code with your smartphone or tablet to get immediate access to the digital version of the instructions. This quick and environmentally friendly solution ensures that you always have the latest information and instructions to hand.

Where can I find spare parts and accessories for the belt conveyor?

The Kanya conveyor technology programme offers a carefully selected range of accessories. From fixed side guides to adjustable side guides, dust brackets or frequency converters to emergency stop switches and much more.

How does the online configurator for belt conveyors work?

The online configurator makes it easy to navigate through the various areas. You select the desired configuration parameters and see a preview of your customised conveyor solution in real time. The entire conveyor can be configured without logging in. If you are registered, you can see the price at any time and can easily download the CAD file (soon available) and the quotation sheet as a PDF. The configuration is saved in your profile. Click here for the instruction video for the online configurator.

Individual enquiry

We are at your disposal for individual enquiries. Please use the form

below and send it to info@kanya.com. Our Team is available to you at

any time by telephone on +41 55 251 58 58.

![[Translate to English:] Kanya AG - Fördertechnik Gurtförderer [Translate to English:] Fördertechnik Gurtförderer](/fileadmin/kanya/produkte/Gurtfoerderer/kanya-ag-foerdertechnik-gurtfoerderer.jpg)

Entdecken Sie unsere hochwertigen Gurtförderer, die eine effiziente und zuverlässige Lösung für Ihren Materialtransport bieten. Mit jahrelanger Erfahrung und maßgeschneiderten Lösungen unterstützen wir verschiedene Branchen bei der Optimierung ihrer Förderprozesse. Erfahren Sie mehr über unsere vielseitigen Gurtförderbänder und finden Sie die passende Lösung für Ihre Anforderungen.

Unsere Gurtförderer bieten viele Features und Vorteile:

- Sichtfenster im Riemenantrieb für Überwachung und Kontrolle

- Vielseitige Anwendungsmöglichkeiten durch den Aluprofilrahmen

- Verbindungsblech Untergestell als Montagehilfe

- u.v.m.