Drive options for belt conveyors: customised solutions

The Kanya belt conveyor offers a wide range of motors for all requirements. We distinguish between the following drive types:

- Direct head drive

- Indirect head drive

- Centre drive direct

- Indirect centre drive

- Drum motor

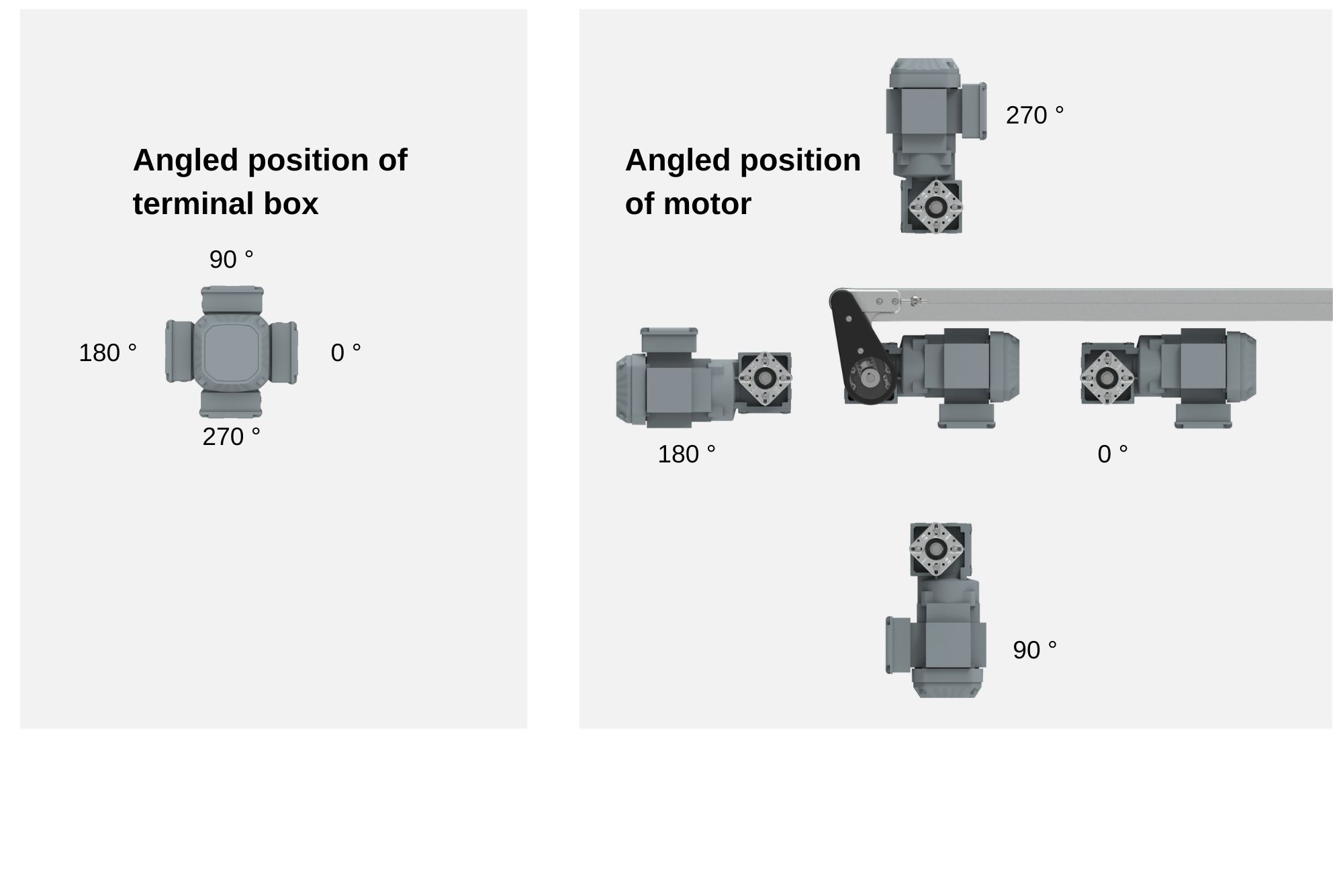

The positioning and orientation of the motor and the terminal box can be defined according to your requirements. The position of the motor and the terminal box can be set between 0°, 90°, 180° and 270°.

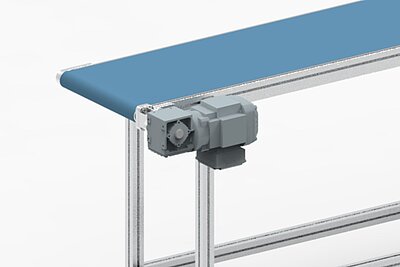

End drive direct

| Position: | Motor directly connected to drive shaft via coupling |

| Advantage: | direct torque transmission, small assembly |

| Motor: | SEW: 3 – 60 m/min NORD: 2 – 79 m/min |

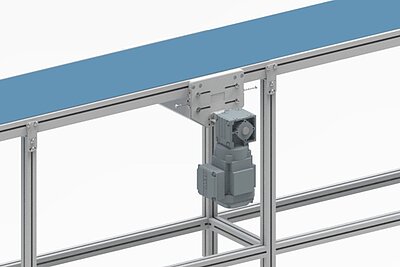

Center drive direct

| Position: | Can be placed along the entire length |

| Advantage | Reversible running direction |

| Motor: | SEW: 3 – 60 m/min NORD: 2 – 79 m/min |

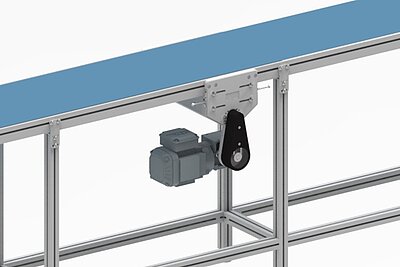

End drive indirect

| Position: | Drive roller connected to the drive with toothed belt |

| Advantage: | Space-saving due to small installation width |

| Motor: | SEW: 3 – 60 m/min NORD: 2 – 79 m/min |

Center drive indirect

| Position: | Can be placed along the entire length |

| Advantage: | Reversible running direction and space-saving due to small installation width |

| Motor: | SEW: 3 – 60 m/min NORD: 2 – 79 m/min |

Drum motor

Position: | Used as a drive roller |

Advantage: | Compact design, without interfering |

Motor: | Interroll: 4 – 52 m/min or |